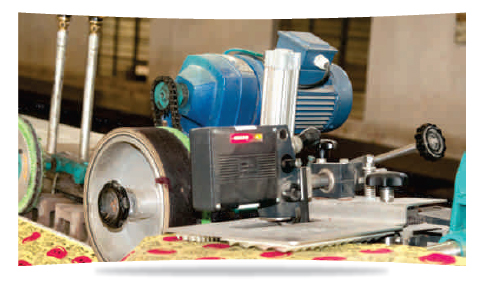

Overfeed Pinning System

Features

- Overfeed sets upto - 20% to 60%

- Lifting can be by means of mechanical or pneumatic.

- Overfeed, underfeed, selvedge can be controlled individually as per need,

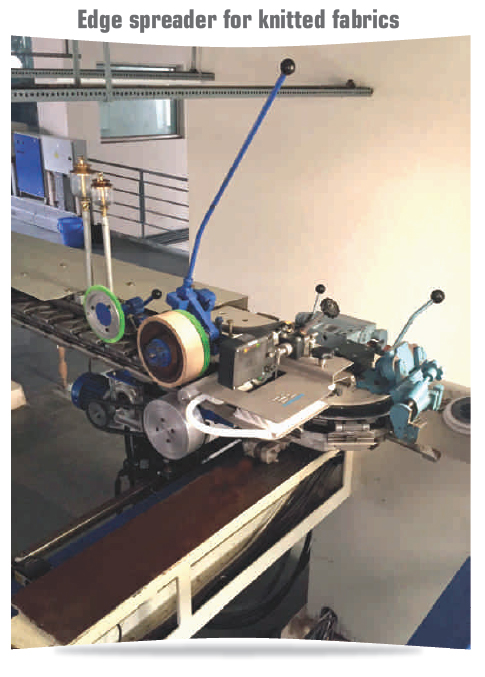

- Double Driven S. S. Scroll Rollers for Woven / Knitted Fabrics.

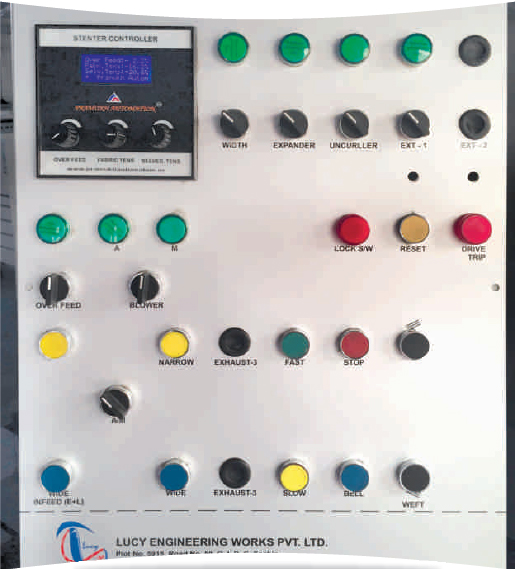

PLC System

- PLC with touch screen for smooth operation & synchronization of overfeed, fabric tension & selvedge tension.

- Blower / Exhaust RPM indicator & controller, temp. Indicator & controller with emergency stop.

- Width adjustment system screen available on request.

- Production data history, electric fault indication & other features on request.

- Machine running hour, meter run & other features available as per requirement.

- Liquid level controller in mangle.

- Radiation pyrometer.

Cockpit

- The control board "cockpit" gives all the information on regarding machine controls.

- Auto cut-off of blowers when m/c. stops in operations.

- T.V. camera with mine & speakers for communications.

- User friendly machine controls.

- Each module temp. can set individually as per need.

- Manual + Fully PLC, both supplied for break free operation or in case of emergency.

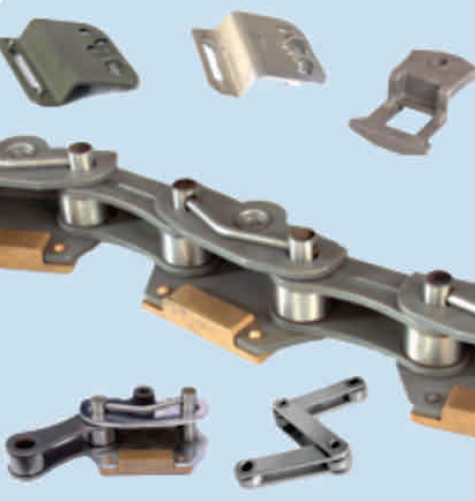

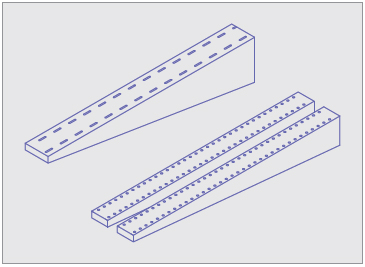

Main Chain

- Chain link made of high carbon steel with high tensile strength.

- Sintered bronze liners.

- Pressure dry cast aluminum alloy pin block/ M. S. Pin blocks.

- Hard chrome plated pin bar.

- Pressure dry cast aluminum pin & clip type blocks. / Only clip type blocks.

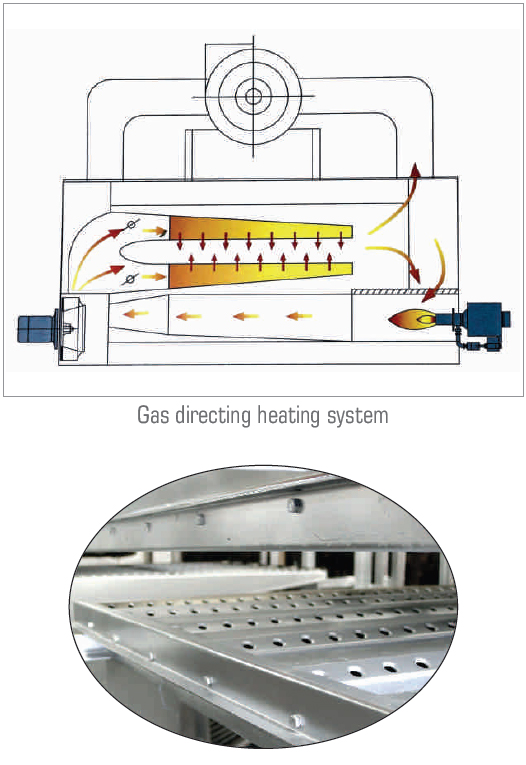

View of Gas Fired Stenter

- Lucy make stenter machine with gas heated arrangement. It is equipped with auto-cut off, safety devices. Temperature raises very fast, shortens the loading time of machine.

- Better efficient insulation for minimum heat losses.

Benefits in Lucy's

- Large heat exchanger in terms of Length to increases suction area.

- Dual air filter net, can be cleaned while machine is in operation.

- High density insulative material for reduction of heatless &without leanages.

- Space saving design for better utility.

- Ideal for all kind of fabrics.

- Water evaporation capacity high from the fabric.

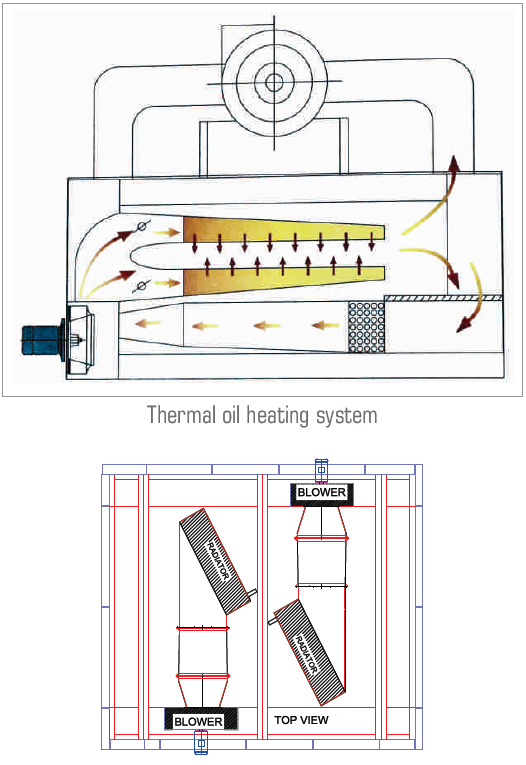

Oil Heating Media

- High efficiency spirally wound hot deep galvanized finned multi pass 1200 / 1600mm long elliptical tube heat exchanger for higher and faster rate of heat transfer with air filter net.

- Dual air filternet on request

- View of bolted nozzle system for easy & quick cleaning of nozzle box.

- No need to remove fingers for cleaning

Nozzle Box (suitable for all types of fabrics)

- Specially designed nozzles with embossed holes giving maximum uniform distribution of hot air & are effected on best drying course. Nozzles are detachable can be removed, cleaned & fitted in very short time - thus help in keeping machine drying efficient constant. Big open able doors with detachable nozzles gives max. access inside the chambers for repairs &cleaning.

- Individual blowers for top-bottom nozzle available on requirement (for coating & in non woven application) / on request.

Blower Assembly & Specification

- Special purpose ring mounted motor used for blower impeller with very very low incident of motor burning & overheating problem.

- 1500 rpm motor & 710 mm diameter with multiple blade as standard supply. 1750 rpm motor available on request.

- Higher energy efficient lE2, 1E3 standard motor as per need.

- Delivery of fabrics in the stenter m/c is available with plaiter, big batching & friction batching / surface winder.

- Static eliminator also provided at plaiter on request.