Technical Specification

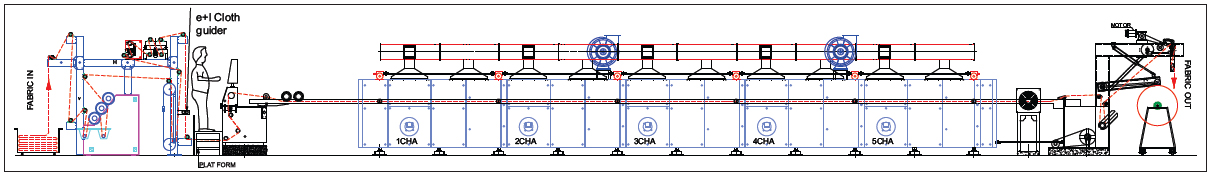

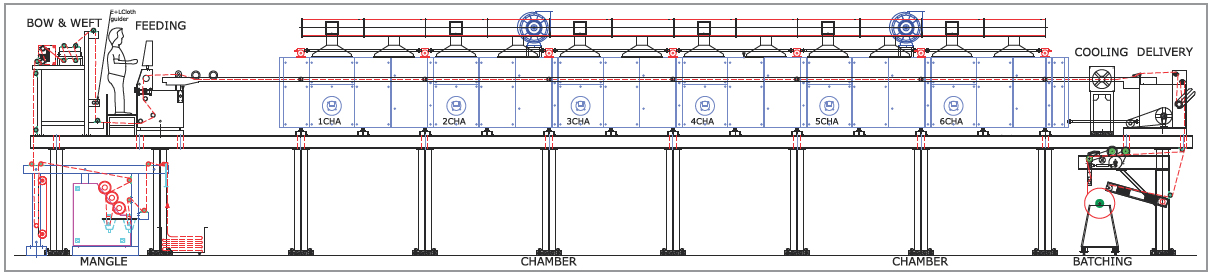

- Speed range : 0 to 20-60-100-140 meters/ min

- Nominal width : 1200mm w.w. To 4000mm w.w. in step of 200mm

- Heating arrangement : thermic fluid/direct gas heating /steam

- Temperature : upto 230°C

- Chamber : 10 feet/ 16 feet (on request)

- Evaporation capacity : upto 120 kg of water/ chamber/ hour for bleached cloth

- Outlet arrangement : plaiter, big/friction batching

- Big batching diameter : up to 1800mm

- Friction hatching diameter : upto 400mm

- Stenter chain : pin chain, clip chain, pin &clip chain

- High efficiency motor IE 1, IE 2, IE 3 standard as per requirement (on request)

- Fully inverted machine

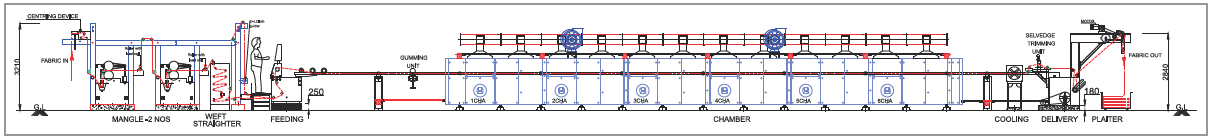

Stenter Line Diagram for Woven Fabric

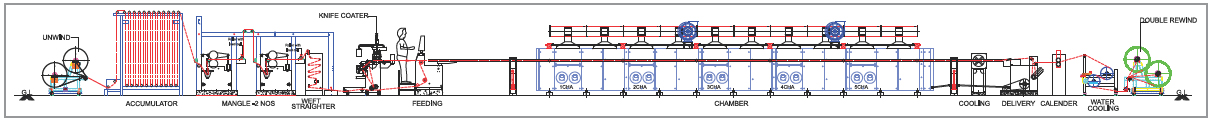

Stenter Line Diagram for Woven Fabric on Scaffolding

Stenter Line Diagram for Knitted Fabric

Stenter Line Diagram for Coating Application

+ Point

- No Need of electronic weft straightener. Bow can be avoided with certain time lag.

- No oil dropping.

- Uniform distribution of heat through the width avoiding drying & finishing problems.

- Minimum heat losses due to radiation.

Extra Accessories For Stenter M/c.

- Cooling / drying cylinder at delivery end.

- Moisture indicator & controller.

- Steaming box with gumming device with suction & trimming unit for knitted fabrics.

- Electronic bow & weft straightener.

- Additional driven guide roller or driven scroll roller as per requirements.

- S. S. Scray unit / J- Box for storage of fabrics.

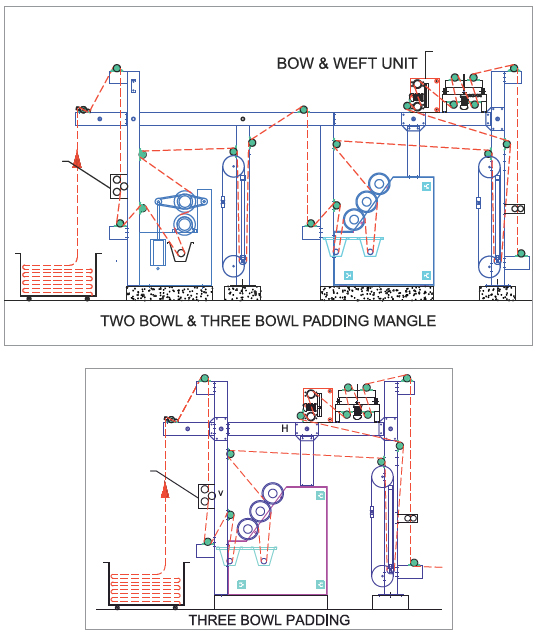

We have carved a niche amongst the most dominant names in this domain, engaged in offering of Three Bowl Mangle. These are highly commended amongst our patrons due to their characteristics such as sturdiness, precise patterns, robustness and much more. Offered product is durable and Corrosion resistant. Furthermore, we promise to deliver this product to our patrons within the assured time frame.

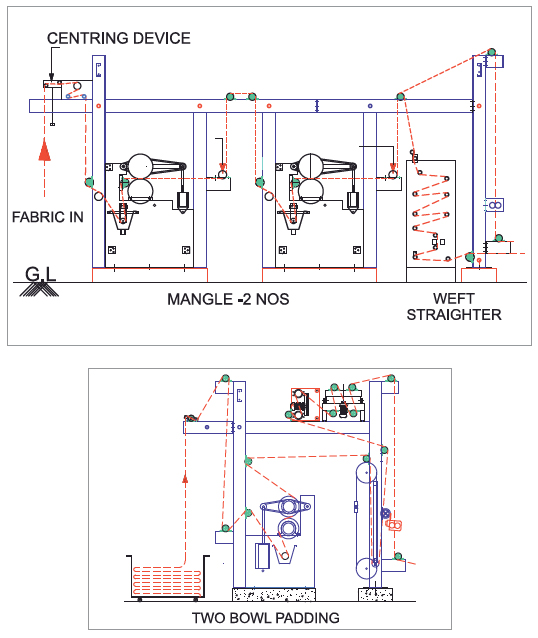

Entry section consists of cloth tension device, centering device or guiders ( both optional ) for keeping the fabrics in center with respect to 3 bpm or 2 bpm or both & a mechanical or pneumatic compensator. 3 bpm consists of 2 dip & 2 nip system. Above the mangle structure, is mounted bow & weft straightner unit.

Load cell supplied on request for tension less synchronization for knitted fabrics & finest variety of cloth with low GSM.

Heavy duty mangle with better squeezing efficiency available on request.

This machine is well-known for excellent squeezing expression & high stenter performance. It is easy to assemble, operate maintain. Lots of textile industries have used the machine & found it very cost effective.

Padders & squeezer :

The squeezing & padding mangle rollers are designed with various type of rubber hardness depending upon the type of fabrics in order to achieve highest possible squeezing expression & highest stenter performance and uniform chemical padding.

Various Line Diagrams

Wet to wet process for knitted fabrics

Wet to wet process for woven fabrics