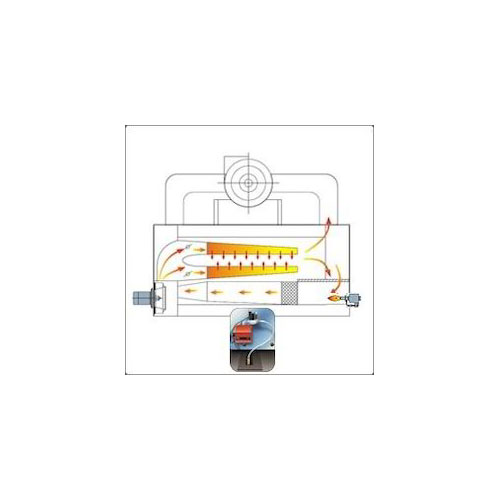

Drying Range

Due to our enormous understanding and massive knowledge of this business, we are involved in the manufacturing of Drying Range. Drying Range Machine we offer is widely used by the maximum number of user in the market. This range is precisely manufactured under the supervision of skilled professionals. This offered machine are widely used for dyeing, hot flue drying and high-temperature baking of cotton, terylene, hemp and other blended fabrics. This product is highly durable, requires low maintenance and hassle free performance.

Cylinder Drying Range

| Roller face (mm) | 1600 - 3600 |

| Cylinder dia | 750 / 800mm |

| Designed pressure | up to 5 bar |

| Design temperature | 135°c |

| Shell material | S. S. 304 |

| Shell thickness | 2.5 mm |

| Teflon coating | 50 microns (on request) |

| Stacks fabricated from m.s. Plates & beams | |

| Hood | S.S. hood with exhaust system (on request) |

| Platform and ladder for ease in cleaning and maintenance. (on request) | |

| High entry with a set of curved rubber expanders | |

| Steam and condensate removal system | |

| Plaiter &/or big batch | |

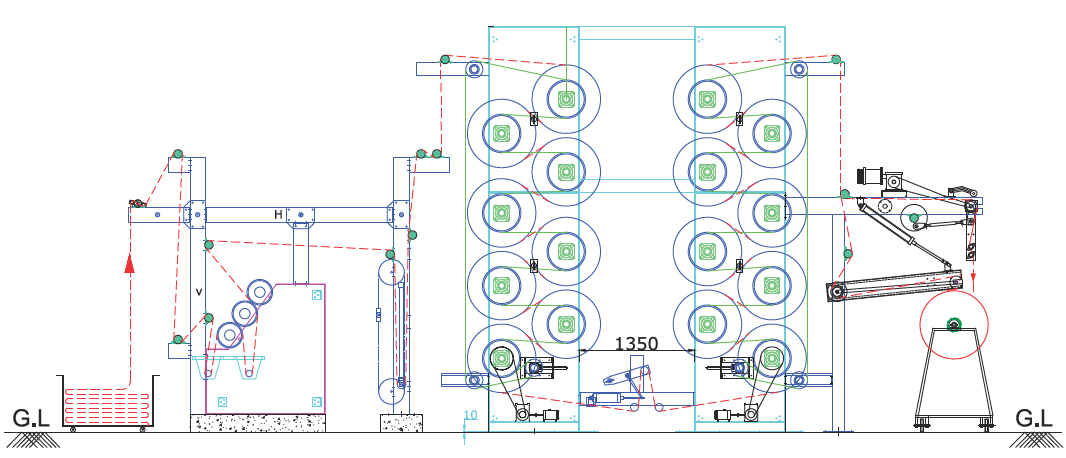

3 Bowl Mangle with 16 Cylinder Drying Range

Equipped with latest technology, our shade dyeing machine is cost textile machinery in the domain. It is tested and found suitable for achieving highest possible dyeing results on fabrics. Cost & time saving technology is used in our shade dyeing machine. Hence many of our clients prefer buying from us for improving the overall productivity of their industries.

- Inclined Type 3 Bowl Shaded Dyeing Mangle

- Inclined Type 3 Bowl Padding Mangle

- Horizontal Type 3 Bowl Shaded Dyeing Mangle

- Horizontal Type 3 Bowl Silicate Padding Mangle

- Rotary Printing Dryer Machine

- 2/3/4/5 Chamber 3 Pass Dryer Machine

- Plaiter unit & Big Batching unit

Product Details :

| Usage/Application | Industrial |

| Shape | different |

| Voltage | 220-380 V standard |

| Weight | 12000 Kilograms standard |

| Model Name/Number | Shade Dyeing Machine |

| Size | 40x12 Feet. standard |

The edge trimmers are mounted at the delivery end of stenter to trim & remove the pinned edges of the web.

The knives can be adjusted to suit various material qualities & to get specific edge trim required.

The suction of trimmed edges is done by a side blower with venture nozzle.

Product Details :

| Usage/Application | Industrial |

| Frequency | Effecient |

| Packaging Size | different |

| Surface Treatment | Fine |

| Color | various |

| Model Name/Number | Selvedge Cutting For Knit Fabrics |

It is quipped with auto - cut off, safety devices.

Temperature raises very fast, shortens the loading time of machine.

Anti-explosive door designs in heating chamber.

Low pollution, easy to maintenance, the most clean heating way for environmental protection.

Product Details :

| Voltage | 24 volts standard |

| Size | required |

| Capacity | different |

| Power Source | Electric |

| Frequency | Efficient |

| Power | Efficient |